RC Model Airplane Engines

When talking about model airplane engines for radio control use, by far the most common type is the glow plug engine, often also called a nitro or even gas engine.

The term gas has widely been used to describe all types of Internal Combustion (IC) powered rc engine, whereas many people - especially in North America - know gas just to mean gasoline, or petrol.

Nitro is a name that's really been adopted from the radio control car world, but is commonly used to describe all glow plug powered rc models. The word nitro comes from nitromethane, an ingredient of glow fuel.

It is fair to say that although glow plug engines are the most common type found in rc airplanes, true 'gas' engines (i.e. petrol powered) have become more popular in recent years and their availability has increased lots. In fact, most of the top model airplane engine manufacturers have turned their attention to bringing out new petrol engines to meet the growing demand for them.

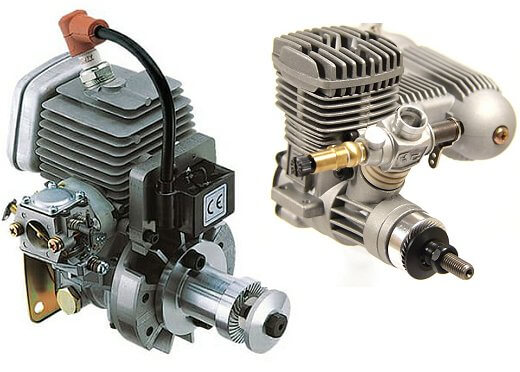

Above: a petrol and glow plug rc aero engine.

2-Stroke vs. 4-Stroke

Just like in the full size world, IC model airplane engines can be 2-stroke and 4-stroke. You might also know these names as 2-cycle and 4-cycle.

The primary difference is that a 2-stroke engine fires per single complete revolution of the crankshaft whereas a 4-stroke engine fires once per two revolutions.

There is also a distinct difference in physical appearance, as you can see from the picture below (these are glow plug engines - 2-stroke on the left, 4-stroke on the right).

This visual difference is the presence of two external pushrods on the 4-stroke engine; internally a 4-stroke engine has valves which need to be opened and closed by the pushrods. A 2-stroke engine does not.

Above: Visual difference between 2-stroke (left) & 4-stroke model airplane engines.

2-stroke model airplane engines have long been the more common of the two types. They produce more power for their size and are much more 'user-friendly' i.e. easier to run and maintain. They are also cheaper to buy because manufacturing costs are lower due to their relative simplicity.

The majority of IC training airplanes will be designed for a 2-stroke engine rather than a four.

That said, it's perfectly okay to put a 4-stroke engine in any suitably sized IC plane. RC plane manufacturers commonly specify two different engine sizes for their planes - one for each engine type.

It's worth noting that, because 2-strokes produce more power for their size than 4-strokes, a 4-stroke engine size recommendation will always be bigger. For example, a '46' size 2-stroke could be replaced with a '61' size 4-stroke.

More on rc engine sizes further down the page.

A 4-stroke engine produces more torque at lower revs and also produces less noise, and the noise it does produce is at a lower frequency. Because of this more realistic sound, it is quite normal for 4-stroke engines to be used in scale rc airplanes i.e. planes that have been modelled from a real airplane type.

As for speed vs. power, a 2-stroke engine will power a plane much faster through the air, whereas a 4-stroke engine will give less speed but more 'grunt'.

![]() While talking about scale planes, don't think that a single-cylinder engine is your only choice. Multi-cylinder engines are widely available these days, up to huge radials like this seven cylinder one from Evolution, shown left.

While talking about scale planes, don't think that a single-cylinder engine is your only choice. Multi-cylinder engines are widely available these days, up to huge radials like this seven cylinder one from Evolution, shown left.

Now that's a model airplane engine!

Here it is in action...

Model Airplane Engine Sizing

Glow plug rc model aero engines, whether 2-stroke or 4-stroke, are expressed as a certain size. This size refers to the engine's capacity in terms of 1/100th of a cubic inch but is usually expressed as just the number eg a .40cu.in. engine would be referred to as a 40 and a .61cu.in. engine would be called a 61.

It's also worth noting that the airplane itself will likely be referred to with the same number i.e. a '40 size plane' would be a plane that has been designed to take a 40 - 46 engine.

Engine size is usually stamped on the side of the engine crankcase, making size-identification very easy.

Petrol engine sizes are also expressed in capacity, but typically in cubic centimeters (cc). For example, a DLE-85 is 85cc (DLE is the brand name).

RC Aero Engine Size Comparison

As a very general rule of thumb, a 4-stroke engine's displacement is approximately 1/3 bigger than an equivalent power 2-stroke. Bear in mind, though, that modern rc engines are more powerful and there are also variations between different brands, engine models etc.

Below is a simple chart of glow plug model airplane engine sizes that you're most likely to encounter, to compare 2 and 4-stroke engine sizes.

| 2-stroke glow (cu.in) | 4-stroke glow (cu.in) |

| .25 | .30 |

| .35 | .46 |

| .40 | .53 |

| .46 | .61 |

| .61 | .81 |

| .75 | 1.00 |

| .90 | 1.20 |

| 1.00 | 1.33 |

| 1.20 | 1.60 |

| 1.40 | 1.86 |

Ringed vs. ABC Glow Plug Engines

You'll likely see two common types of rc glow plug engine; ringed and ABC.

The primary difference is in the compression seal. A traditional ringed engine uses an iron ring inserted around the aluminium piston that presses against the steel cylinder wall. This keeps the fuel/air mixture inside the compression chamber and oil out of it, as in a full size engine.

An ABC engine does not have a ring but instead features a tapered sleeve inside the cylinder.

The letters ABC refer to the materials used; the piston is aluminium, the cylinder is brass and the inside of the cylinder (sleeve) is chrome plated.

The sleeve is gently tapered inwards towards the top of the compression chamber and expands outwards as the engine heats up. The tolerances between sleeve and piston are such that a perfect seal is created when the engine is at running temperature.

ABC glow plug engines are supposedly the better performers, but each engine type has its loyal band of followers and ringed engines are in no way endangered! I have tried both types and haven't really noticed a huge difference between the two.

Glow Plugs for Model Plane Engines

Where a petrol engine uses a spark plug to ignite the fuel/air mixture within the compression chamber, an rc model airplane glow engine uses a small glow plug.

Where a petrol engine uses a spark plug to ignite the fuel/air mixture within the compression chamber, an rc model airplane glow engine uses a small glow plug.

The plug filament needs to be heated up initially using an external glow plug igniter, but once the engine is running the heat generated within the combustion chamber, and a slight chemical reaction between an ingredient of the fuel (methanol) and the plug filament, keeps the filament glowing continuously and so ignites the fuel/air mixture on each revolution.

Glow plugs for rc model airplane engines can be bought with different 'heat ratings' depending on the engine and flying conditions. Always follow the engine manufacturer's recommendations when choosing a suitable plug.

The plugs can fail at any time by the filament burning out, and without a plug the engine won't run. For this reason it's a very good idea to have a selection of spare plugs with you whenever you fly.

Similarly, always be sure that your igniter is charged because it's sickening to get to the flying field only to find that you can't heat the glow plug to get the engine running!

RC Plane Engine Carburation

Model airplane engines have a simple carburettor, generally speaking. It's typically located on the top front of the engine crankcase, although some engines have the carb located at the rear, for safer adjusting (to keep fingers well clear of the propeller).

Model airplane engines have a simple carburettor, generally speaking. It's typically located on the top front of the engine crankcase, although some engines have the carb located at the rear, for safer adjusting (to keep fingers well clear of the propeller).

The carb consists of a venturi where the fuel and air mix, idle screw to adjust the idle speed of the engine, mixture screw, or 'needle valve', to allow fine tuning of the fuel/air mixture and hence the high-end RPM and a rotating barrel.

This barrel features an external control horn that is connected to the throttle servo linkage, and the barrel rotates as the throttle servo responds to your stick inputs. As you push up the throttle stick on the Tx, the barrel turns and opens the venturi to let more air and fuel into the combustion chamber. As you shut down the throttle, so the barrel rotates back again and the mixture is reduced by the closing of the venturi.

2-stroke Operation

A 2-stroke glow plug engine works thus...

As the fuel passes into the carburettor it mixes with air being sucked in through the open venturi, this fuel/air mixture then passes through transfer ports that run vertically up the outside of the piston chamber. These ports exit into the combustion chamber above the piston. The mixture gets forced up into the combustion chamber every time the piston completes a downward stroke.

Once inside the combustion chamber the fuel/air mixture gets compressed by the piston rising back up. This rapid compression greatly increases both the pressure and temperature of the fuel/air mixture, and the red hot filament of the glow plug ignites the mixture when the piston reaches Top Dead Centre (TDC), assuming that the ignition timing is correct (ignition timing can be advanced or retarded if necessary by fitting a different length glow plug, or altering the height of the current plug by using shims or washers).

The resulting explosion forces the piston back down again. As the piston moves downwards, the burned gases are expelled through the exhaust ports, and the cycle begins again.

Below is a great video showing the construction and workings of a typical 2-stroke model airplane engine. The video comes courtesy of Juan Seren (https://jas-3d.blogspot.com/).

Model airplane engines can be very temperamental sometimes and require what seems to be endless adjustments to keep them running smoothly. Even when correctly tuned and run-in, it is perfectly normal for the needle valve to require regular adjustment before, and even during, each flying session due to changing atmospheric conditions.

Cold and damp weather can cause starting and running problems for rc glow plug engines, as can poor quality or old fuel, air leaks in the fuel system and other issues, but the biggest cause of a non-starting engine is often simply a burnt out glow plug!

Other RC Model Airplane Engine Types

While glow plug engines are by far the most common type found on the flying field, they are not the only type.

Petrol rc plane engines, such as this Evolution 80GX for example, are becoming increasingly common.

Petrol rc plane engines, such as this Evolution 80GX for example, are becoming increasingly common.

Traditionally petrol engines have only been available in larger sizes (say upwards of 50cc) but thanks to better technology smaller petrol engines are now readily available, right down to 10cc which equates to a 40 size glow plug engine.

Both 2-stroke and 4-stroke petrol engines are available for the radio control flying hobby whereas previously 4-stroke petrol engines were both elusive and expensive.

More impressively, some smaller petrol rc plane engines such as the OS GGT engines are using glow plug technology, making them easier to start and require less maintenance. In short, the convenience of glow combined with the economy of petrol!

Cost is a major factor of a petrol rc plane engine. Regular unleaded petrol is a lot cheaper than glow fuel, and although the initial cost of a petrol engine might be more, the ongoing running costs will be less.

Diesel engines are another choice but are probably the least common of all IC model aero engines.

Diesel engines are another choice but are probably the least common of all IC model aero engines.

Diesel model airplane engines such as the PAW (Progress Aero Works from the UK) shown right are typically used in vintage rc airplanes to keep the model as authentic as possible; such engines were being manufactured long before glow plug technology and so were the first IC engines to be used in radio control flying decades ago, having seen great success in free-flight models.

Diesel engines do not use any form of plug for ignition but instead rely on the fuel/air mixture inside the combustion chamber to ignite from a process known as adiabatic heating, as the piston moves up and down.

The pressure inside the chamber (compression) can be increased or decreased by turning a threaded screw on top of the cylinder head; increasing the compression aids ignition of the fuel/air mixture. The fuel is a special mix that has a high ether content, which is easily ignited.

Anyone who has used a diesel engine in a model plane will know that beautiful smell of burning castor! I have very fond memories of my first free-flight plane, a Tomboy designed by well-loved UK model plane designer Vic Smeed.

If memory serves me, my Tomboy had a Mills .75 diesel that my dad gave me, and I used to love the smell and the noise it produced. Happy days!

Whichever model plane engine type you use, you can be sure that it will bring you a richer rc flying experience. The presence of an actual engine in a plane (as opposed to an electric motor) brings a higher level of learning and understanding, and a deeper involvement with your airplane. Quite simply, if you're a true lover of IC engines in any shape or form, then you'll get total satisfaction from flying an IC powered airplane!

Model Airplane Engine Reading

![]()

'2-Stroke Glow Engines For R/C Aircraft'![]() is a very informative book on the subject and is an excellent guide to understanding model airplane glow engines.

is a very informative book on the subject and is an excellent guide to understanding model airplane glow engines.

"This book is undoubtedly one of the best (if not THE best) texts on the subject I've encountered. The section on correct running-in of engines should be included in the box with each and every 2-stroke R/C engine sold...(customer review extract) Read more.![]()